Quality

At Sunrise Technologies, quality isn’t just a department; it’s the bedrock of everything we do. For the defense, automotive, medical equipment, and machine tool industries, where performance, reliability, and safety are non-negotiable, our commitment to uncompromising quality is absolute. We embed rigorous quality control into every stage of our CNC machining process, ensuring that every component we deliver precisely meets the most stringent specifications and exceeds your expectations.

Our core belief is that superior quality is achieved through a combination of:

Proactive Planning: We integrate quality considerations from the initial design review through to final delivery.

Precision Technology: We leverage state-of-the-art machinery and inspection tools.

Skilled Expertise: We empower our team with continuous training and cultivate a culture of excellence.

Continuous Improvement: We constantly refine our processes to enhance both quality and efficiency.

Quality Policy

“Sunrise Technologies is committed for enhancing customer satisfaction and continually improve Quality Management Systems by meeting customer requirements, continual improvement of the processes, involvement of employees and complying to applicable statutory requirement”

We’re proud to be an ISO 9001:2015 certified manufacturer by TUV-India. This certification is a testament to our robust Quality Management System (QMS), demonstrating our unwavering commitment to:

Consistently providing products and services that meet customer and regulatory requirements.

Enhancing customer satisfaction through the effective application of our system, including processes for improvement.

Maintaining a disciplined and documented approach to all aspects of our operations.

Our Unwavering Quality Process

Every component manufactured at Sunrise Technologies undergoes a multi-stage, rigorous quality assurance process:

Material Sourcing & Verification:

We use only the best quality materials sourced from approved, reputable suppliers.

All incoming materials are meticulously inspected and accompanied by Material Test Reports (MTRs) to verify composition and properties, ensuring full traceability.

In-Process Quality Checks:

During every machining operation, our skilled machinists perform continuous, real-time inspections using precision instruments.

Critical dimensions are verified at each stage to detect and correct any deviations immediately, preventing downstream issues.

Our advanced CNC machines are equipped with in-process probing capabilities for automated measurement and adjustment, enhancing accuracy and consistency.

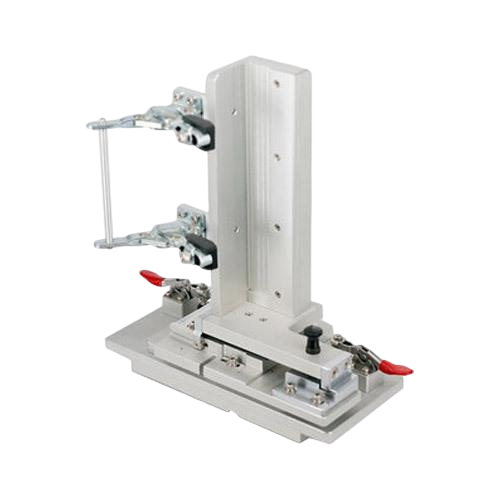

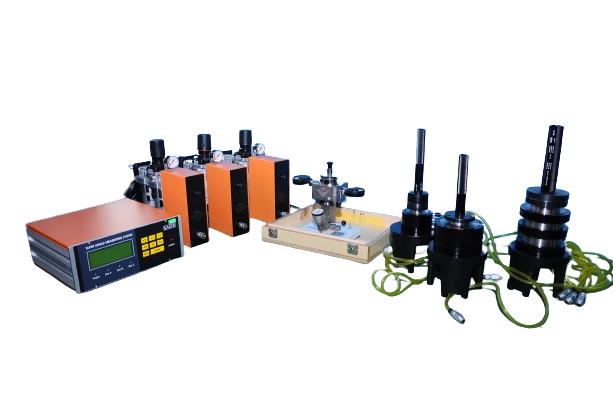

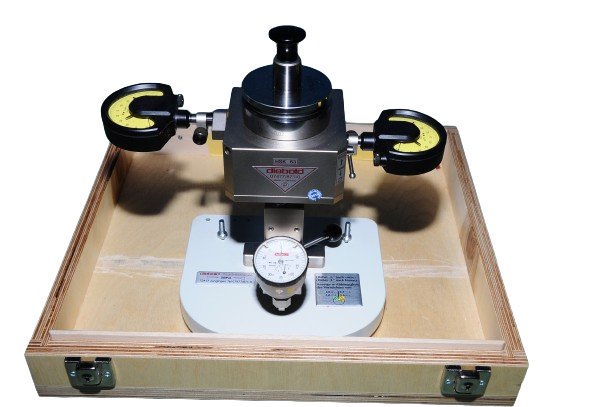

Dedicated Quality Control & Metrology Lab:

Our climate-controlled, state-of-the-art quality lab is equipped with advanced metrology equipment:

Surface Roughness Testers: To verify critical surface finish requirements, vital for functional performance and aesthetics.

A Full Range of Calibrated Hand Tools: Including micrometers, calipers, bore gauges, and height gauges, all regularly calibrated to national and international standards.

Every product we make is rigorously tested at every stage by our certified quality technicians to ensure it meets every specified dimension and requirement.

Final Inspection & Documentation:

Before shipment, all finished components undergo a comprehensive final inspection to confirm 100% adherence to customer specifications.

Detailed inspection reports, Certificates of Conformance (CoCs), and Material Test Reports (MTRs) are provided with every order, ensuring complete traceability and accountability.

Industry-Specific Quality Adherence

Our robust QMS is designed to meet and exceed the specific quality demands of the industries we serve:

Defense: We adhere to stringent specifications for mission-critical components, including material traceability, robust manufacturing processes, and compliance with relevant military and government standards.

Automotive: We deliver components with tight tolerances, high reliability, and consistent performance for demanding automotive applications, often aligning with PPAP requirements and IATF 16949 principles.

Medical Equipment: We manufacture ultra-precise, often biocompatible, components for surgical instruments, implants, and diagnostic devices, with a deep understanding of ISO 13485 principles and FDA QSR requirements.

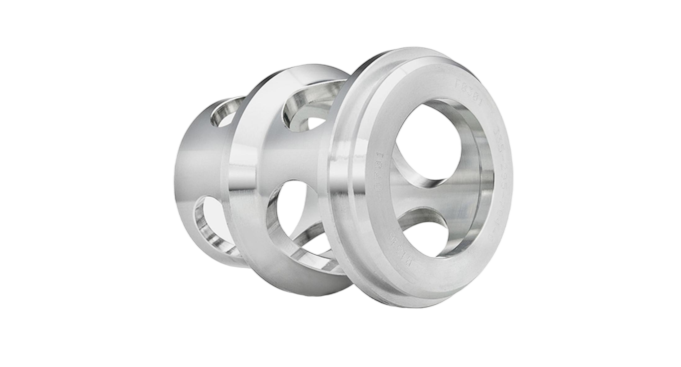

Machine Tools: We produce high-precision components that are foundational to the accuracy, rigidity, and longevity of industrial machinery, where even minute deviations can impact performance.